자동 플래너 바이니히 유니마트 800(AUTOMATIC PLANER AND MOULDER WEINIG UNIMAT 800)

작성자최고관리자

등록일2024-05-31

조회수 247

본문

AUTOMATIC PLANER AND MOULDER WEINIG UNIMAT 800

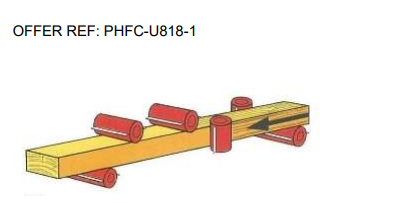

Spindle arrangement no. 018 (B-R-L-T-T-B) / Made in China

TECHNICAL DATA

Working width (with tool cutting circle 125 mm) 30 - 310 mm

Working height (with tool cutting circle 125 mm) 10 - 200 mm

Spindle Diameter 50 mm

Spindle Speed 6000 rpm

10 pcs Standard feed pendulums from above

5 pcs Standard driven rollers in the machine table

6 pcs Straight jointer, Manual. For all spindles

4 pcs Outboard bearings. For all horizontal spindles

1 ST - BOTTOM HORIZONTAL SPINDLE

Motor 18.5 KW (25 HP)

Tool cutting circle 125 - 180 mm

2 ND - RIGHT VERTICAL SPINDLE

Motor 15 KW (20 HP)

Tool cutting circle 125 - 250 mm

Setting range axial 80 mm

3 RD - LEFT VERTICAL SPINDLE

Motor 15 KW (20 HP)

Tool cutting circle 125 - 250 mm

Setting range axial 80 mm

Pressure shoe in front of left spindle, incl. 2 lateral pressure, pneumatic.

Sliding surface to improve ease of use and extended life time on left spindle

4 TH - TOP HORIZONTAL SPINDLE

Motor 18.5 KW (25 HP)

Tool cutting circle 125 - 250 mm

Setting range axial 40 mm

Split pressure shoe in front of 1st top spindle, adjustable to tool cutting circle and receding from tool, pneumatic.

5 TH - TOP HORIZONTAL SPINDLE

Motor 15 KW (20 HP)

Tool cutting circle 125 - 250 mm

Setting range axial 40 mm

Split pressure shoe in front of 2nd top spindle, adjustable to tool cutting circle and receding from tool, pneumatic.

6 TH - BOTTOM HORIZONTAL SPINDLE

Motor 15 KW (20 HP)

Tool cutting circle 125 - 250 mm

Setting range axial 45 mm

SPINDLE IN GENERAL

All moulding spindles highly concentric running.

Lubircation points for axial spindle movement.

- 20 pcs Jointingstone for straight HSS and Stellite knives, diameter 12 x 32 mm

- 6 additional sets of spacing collars, clamping length 170 mm, diameter 50 mm

FEED SYSTEM

Feed speed electronically variable incl. brake 6 – 60 m/min.

Motor 11 KW (15 HP)

Durofer pointed tooth rollers self-cleaning with depth limitation

- First feed roller with free-wheel gear, in lieu of the standard roller

Setting range of the feed rollers opposite left spindle, axial 35 mm

- Extension of the pendulum arbor opposite the left spindles to 210 mm

MACHINE ELECTRIC

- Operating voltage 380 Volt, 60 Cycles

Electric version according to DIN VDE 0113, electric equipment of industrial machines EN60204, IEC-204-1.

Additional electrical regulations are not taken into consideration.

Prior to operating frequency-controlled devices or facilities in locations threatened by fire hazards an FI protective

circuit breaker sensitive to universal currents according to DIN VDE 0100-482 has to be installed by the client.

- Electrical system of the moulder prepared for infeed mechanization

- Electrical system of the moulder prepared for outfeed mechanization

- Switch cabinet separate from the machine with 2.5 m flexible cable

- Operating panel separate from control cabinet, distance 4.5 m.

MACHINE BASE, TABLES AND FENCES

- Infeed table 1,2 m long with removable roller conveyor extention to 2 m

Including 2 driven rollers above the table and 1 driven, toothed roller in the table for levelling the workpieces

Machine table and fences solid chromium-plated (excluding infeed table and special table plates)

- Automatic lubricant pump to remove resin from machine table.

Two feed rollers and 1 driven table roller 210 mm wide in the machine outfeed

Three driven rollers in the machine table, hardened

PRESSURE ELEMENTS AND GUIDES

- Lateral pressure roller at the infeed table, pneumatic

Guiding fence, left, manually height adjustable, for precise guidance of workpieces below top spindle

Pressure rollers from above, pneumatic

- Receding pressure roller from above, for uncomplicated tool exchange opposite right spindle, pneumatic.

MACHINE OPERATION

Clamping levers for radial and axial spindle adjustments color codes for sure identification.

Machine without control unit and with mechanical digital read-outs.

For manual adjustment and positioning of spindles and pressure elements.

Electric height adjustment of top spindle and feed

Central position of lubrication points at the front side of the machine

SAFETY AND NOISE PROTECTION

Safety enclosure

Easily liftable safety hood with window covers the entire work area (feed and spindles) and protects against

mechanical hazards.

When the safety hood is lifted, tool holders and feed are automatically switched off.

The safety enclosure cannot be opened during automatic operation if machine is supplied according to CE

regulations (in the single market)!

- Two interior lights in the safety hood

The Illustrations in this offer can include special equipment, which do not belong to the range of your offer.

WARRANTY

The warranty period for this machine is 12 months for single shift operation from installation completion

or 6 months for two shift operation and 3 months for more than 2 shifts.

Extension of guarantee period:

Contrary to our General Standard Terms and Conditions the warranty period is 24 months in single-shift operation,

12 months in two-shift operation and 6 months in multiple-shift operation.

For this extension of the guarantee period, 2% of the machine price must be charged!

SERVICE

Incl. Machine installation and test running, training by Hanyang Universal

Excl. Unloading, electric connection, pneumatic connection, dust extraction pipe connection

PRICE

FCA [Free Carrier] Yantai, China

according to Incoterms 2010, Packaged and loaded in container

-------------

TOTAL PRICE FOR THE MACHINE : EUR 220,286

=============

- PREV 파셉 마이크로파 건조기 영상

- NEXT 제목이 표시됩니다